How precise is laser cutting? Laser cutting is highly precise, achieving cutting accuracies down to 10-20 microns or even smaller. In most cases, laser cutters can consistently operate with an accuracy of ±0.05~±0.2 millimeters (0.002~0.008 inches), often achieving tolerances of ±0.1 millimeters (0.004 inches) or less. This precision largely depends on the type of laser source, the optical system, and the accuracy of the motion control system.

Factors Affecting Fiber Laser Cutting QualitySpot Size Control: After passing through the cutting head lens, the laser beam forms a tiny focal point. The smaller the focal spot, the higher the cutting precision. The smallest spot size can reach 0.01 mm.

Factors Affecting Fiber Laser Cutting QualitySpot Size Control: After passing through the cutting head lens, the laser beam forms a tiny focal point. The smaller the focal spot, the higher the cutting precision. The smallest spot size can reach 0.01 mm.

Stable Machine Bed: Precision mechanical components and a stable base keep the laser head steady during cutting, preventing errors caused by vibration or movement.

Workpiece Thickness: The thicker the workpiece, the lower the cutting precision and the wider the kerf. The laser beam is conical, resulting in a tapered kerf. Thinner materials (e.g., 0.3 mm thick) have narrower kerfs compared to thicker materials (e.g., 2 mm thick).

Material Type: The smoother or thinner the metal sheet or material used, the more precise the cut. To achieve optimal cutting, appropriate parameters must be set according to the material type.

Lower Cutting Speeds: During laser cutting metal, lower cutting speeds give the laser beam more time to act on the material, which allows the material to absorb heat more evenly, resulting in a more consistent melting process. In addition, slower speeds allow the operator or automated cutting system to control the laser cutting path more accurately, reducing errors and improving the repeatability and consistency of the cut.

Focus Position Control: The smaller the focal depth of the focusing lens, the smaller the focal spot diameter. Therefore, controlling the focal position relative to the material surface is crucial.

Perforation technology: During laser cutting, a small hole is usually punched in the sheet and the cut is made from that point.

Nozzle Design and Airflow Control: In laser cutting steel, oxygen and the focused laser beam pass through the nozzle to the material, forming an airflow beam. A large volume of high-speed airflow is needed to generate enough oxidation reaction and momentum to blow out the molten material.

Manufacturers: How to Improve Laser Cutting Quality of Metal?Hardware Upgrades: The precision of fiber laser cutting machines largely depends on hardware components such as the laser source, optical system, and control system. With breakthrough in manufacturing technology, manufacturers have significantly improved the accuracy and stability of these optical components. DPLASER cutting machine beds made from high-quality carbon steel are more stable and durable. High-strength machine beds undergo stress relief annealing at 600°C, resulting in strong structural rigidity, minimal deformation, and reduced vibration, ensuring cutting precision.

Manufacturers: How to Improve Laser Cutting Quality of Metal?Hardware Upgrades: The precision of fiber laser cutting machines largely depends on hardware components such as the laser source, optical system, and control system. With breakthrough in manufacturing technology, manufacturers have significantly improved the accuracy and stability of these optical components. DPLASER cutting machine beds made from high-quality carbon steel are more stable and durable. High-strength machine beds undergo stress relief annealing at 600°C, resulting in strong structural rigidity, minimal deformation, and reduced vibration, ensuring cutting precision.

Computer Numerical Control (CNC): Laser cutting machines equipped with CNC systems can control the movement of the laser head with high precision. Operators can program these systems to follow exact cutting paths, ensuring precise and repeatable cuts.

Advanced Algorithm Application: In recent years, advanced algorithms like artificial intelligence and machine learning have been widely used in laser cutting machines. These algorithms can continuously optimize the cutting system and parameters by learning from large data samples, thereby enhancing the machine’s precision.

Increased Automation: High-precision automated control systems ensure accurate processing during fast cutting, reducing human error and operational mistakes.

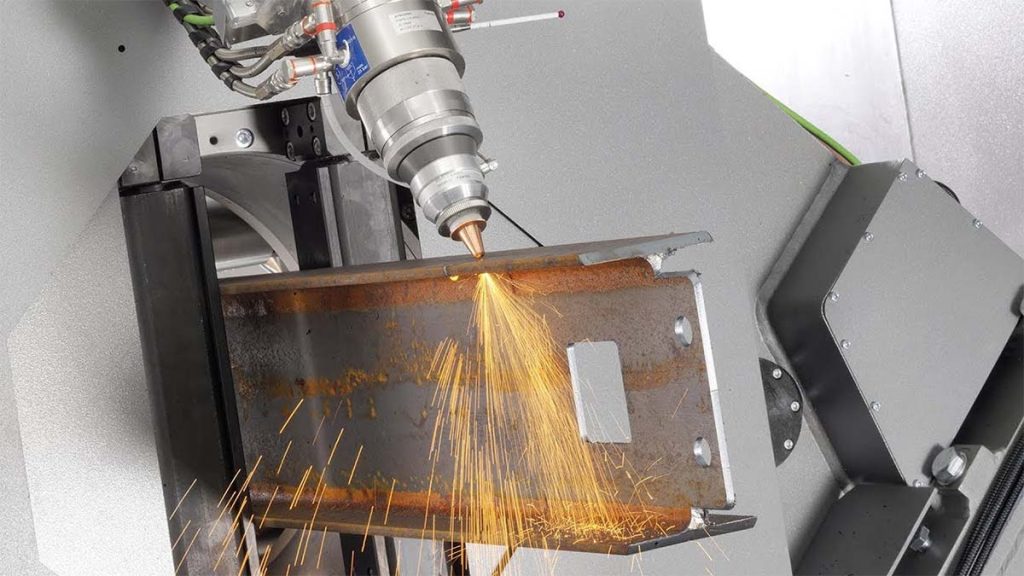

How Pipe Laser Cutters Improve Precision and Efficiency?

Laser cutting pipe precision and efficiency are influenced by several factors including chuck installation accuracy, the precision of the pipe itself, and clamping accuracy. To minimize errors, it is essential to ensure both machine and pipe precision. CNC pipe cutting systems offer dynamic error compensation solutions, such as using follow-up supports to reduce wobble during pipe rotation and employing centering techniques (real-time centering during processing) to minimize internal centering errors in each pipe segment.

Tips for Maintaining the Laser Cutting AccuracyRegular Cleaning and Inspection: Periodically remove dust, debris, and residue from the work area, optical components, and other critical parts to keep the machine clean. Dirty or damaged optical elements can scatter or absorb the laser beam, leading to reduced precision.

Tips for Maintaining the Laser Cutting AccuracyRegular Cleaning and Inspection: Periodically remove dust, debris, and residue from the work area, optical components, and other critical parts to keep the machine clean. Dirty or damaged optical elements can scatter or absorb the laser beam, leading to reduced precision.

Frequent Consumable Replacement: Regularly inspect and replace consumables such as nozzles, lenses, and focusing optics to ensure optimal performance.

Alignment and Calibration: Follow the manufacturer’s guidelines for regular alignment and calibration procedures to ensure the laser beam and cutting head are correctly aligned.

Focal Length Adjustment: Adjust the focal length based on the material thickness to ensure the laser beam is accurately focused on the workpiece.

Machine Structure Maintenance: Regularly check the machine’s structural components, including the frame, rails, and gantry, for signs of wear, damage, or misalignment.

Material Securing: Inspect the material for defects or warping and ensure it is properly supported and fixed on the cutting table.

Optimizing Cutting Parameters: Continuously fine-tune and optimize cutting parameters (such as laser power, cutting speed, and assist gas pressure) to suit the specific material and thickness being processed.

What Factors Will Reduce the Accuracy of Laser Cutting?Improper Cutting Parameters: Laser cutting parameters, such as laser power, cutting speed, gas pressure, and focal position, directly affect the energy density and stability of the laser beam, impacting cutting precision. Users should select appropriate cutting parameters based on the material, thickness, and shape, typically through trial and error and sample cutting. For assistance with optimizing parameters, please contact our engineers for free sample cutting.

What Factors Will Reduce the Accuracy of Laser Cutting?Improper Cutting Parameters: Laser cutting parameters, such as laser power, cutting speed, gas pressure, and focal position, directly affect the energy density and stability of the laser beam, impacting cutting precision. Users should select appropriate cutting parameters based on the material, thickness, and shape, typically through trial and error and sample cutting. For assistance with optimizing parameters, please contact our engineers for free sample cutting.

Component Wear or Damage: Key components of metal fiber laser cutters, including the laser head, optical lenses, and nozzles, are subject to wear or damage due to high temperatures, pressures, and dust over time. This can affect the quality and direction of the laser beam, reducing cutting precision. Regularly inspect these components to ensure proper function and replace any damaged parts promptly.

Machine Movement Instability: The stability of the cutting machine significantly impacts laser cutting precision. Check the gantry, guide rails, lead screws, and servo motors for excessive vibration or friction during operation, as these issues can lead to unstable movement and affect the performance and accuracy of the laser head. Ensure all components operate smoothly to minimize unnecessary vibration and friction.

Poor or Uneven Material Surface Quality: A material’s poor or uneven surface quality can affect the reflection and transmission of the laser beam, impacting its energy density and stability. This can lead to uneven cut widths, increased burrs, and severe burn marks, all of which reduce cutting precision. To improve cutting results, use high-quality materials with a smooth and uniform surface.

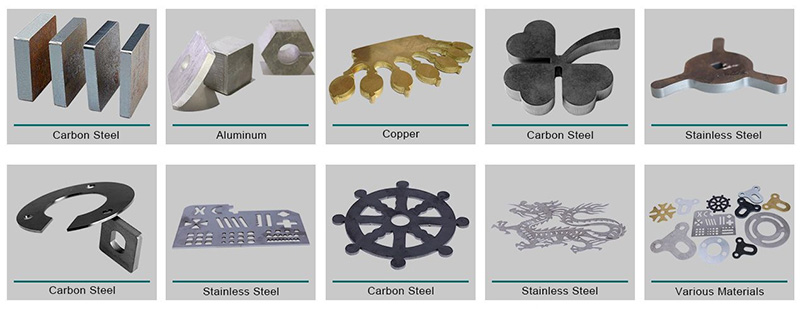

Choose the best Laser Cutting Machine for Precision CuttingDapeng’s metal fiber laser cutting machines, known for their excellent performance, reliable quality, and comprehensive after-sales service. Our machines feature imported fiber lasers, high-precision drive systems, and intelligent control systems, offering high cutting precision, fast cutting speeds, a wide cutting range, and ease of operation. They are suitable for cutting various metals, including stainless steel, carbon steel, aluminum alloys, and copper alloys, and are widely used in industries such as machinery manufacturing, automotive production, metal processing, and parts manufacturing.

Choose the best Laser Cutting Machine for Precision CuttingDapeng’s metal fiber laser cutting machines, known for their excellent performance, reliable quality, and comprehensive after-sales service. Our machines feature imported fiber lasers, high-precision drive systems, and intelligent control systems, offering high cutting precision, fast cutting speeds, a wide cutting range, and ease of operation. They are suitable for cutting various metals, including stainless steel, carbon steel, aluminum alloys, and copper alloys, and are widely used in industries such as machinery manufacturing, automotive production, metal processing, and parts manufacturing.

If you have metal laser cutting needs, please contact Dapeng for a customized laser cutting solution.